the Minerva way

Maximize product development speed and quality systems efficiency—The Minerva Way

Expert process development support, quality systems, and investigation execution, responding to technical and quality issues with a specialized, multidisciplinary team.

Knowledge and risk-based process and quality system improvements for development, commercialization and ongoing manufacturing.

Improved quality and production outcomes through knowledge and risk-based design and development, reliability experts, and visual models.

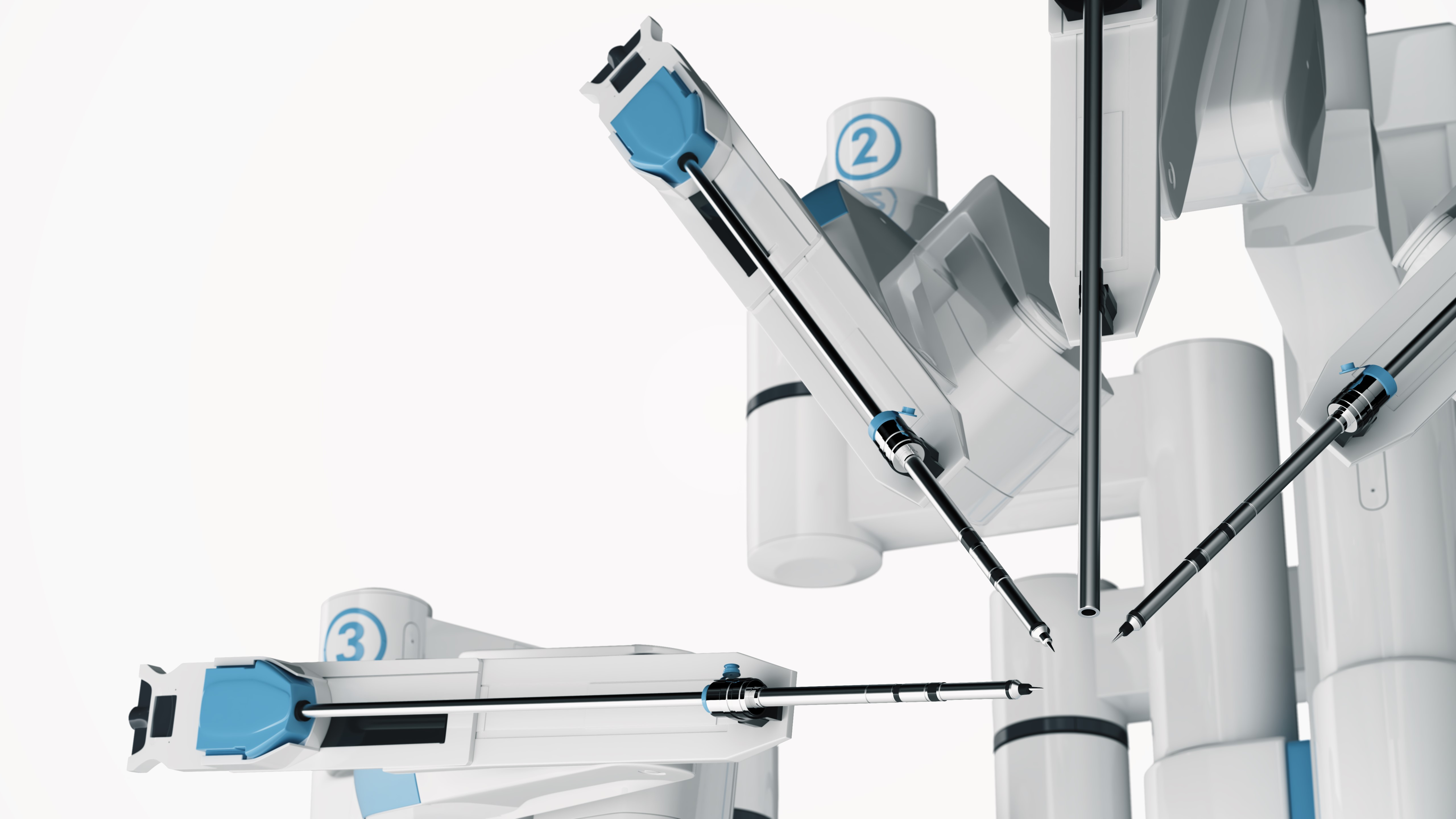

Half a decade supporting risk-based medical robot development and commercialization using fully digital knowledge and quality systems.

From startups to large corporations, Minerva provides personalized technical services

for product discovery, development, and commercialization.

Delivering faster, smarter, and better results for clients, doctors, and patients through a knowledge and risk-based approach, using advanced visualization and digitalization techniques

the Minerva way.

Let’s work together to achieve your development, operations, and quality objectives.

Our ultimate goal is to support your development, operations, and quality objectives, ensuring patients receive high-quality, accessible devices and therapies delivered on time.